As a professional supplier of industrial system solutions, torchi can design a single evaporation system or optimize a variety of processes in combination with the use characteristics of different evaporation systems, so as to achieve better results. According to different materials and working conditions of customers, we can carry out process calculation and live simulation to ensure that the separation effect can be achieved.

Torchi has public system design and R & D center, equipped with process, piping, I & C, equipment and other professionals. There are also professional R & D personnel who use P3D and other software for auxiliary design and use scientific means to ensure the rationality of design and R & D.

Torchi has its own product center, which is responsible for the manufacturing, assembly and testing of the system. Most of the work is completed in the factory, which reduces the amount of construction on site, improves the quality and speeds up the progress.

Torchi has the construction qualification of pipeline installation, anti-corrosion and heat preservation, as well as professional installation, commissioning and maintenance personnel, which not only effectively ensure the implementation of new projects, but also provide guarantee for the maintenance and repair of industrial systems.

User customized design

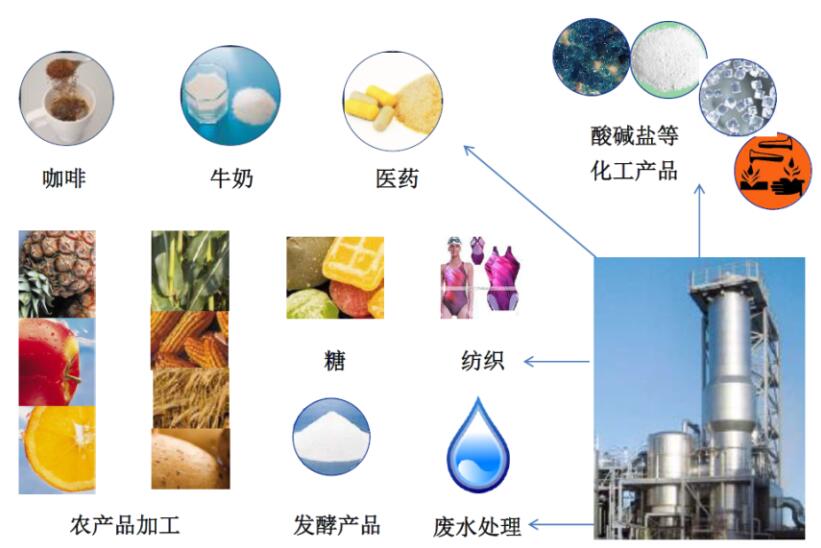

● Machinery & surface treatment industry (auto, aerospace and other parts)

● medical industry (pharmacy, cosmetics)

● chemical industry

● waste treatment, biofuel industry

● optoelectronic and microelectronic industry

● food and beverage industry

● printing and packaging industry

● power industry

● oil and gas industry

● mining and primary metal smelting

● and other industrial system maintenance and replacement services

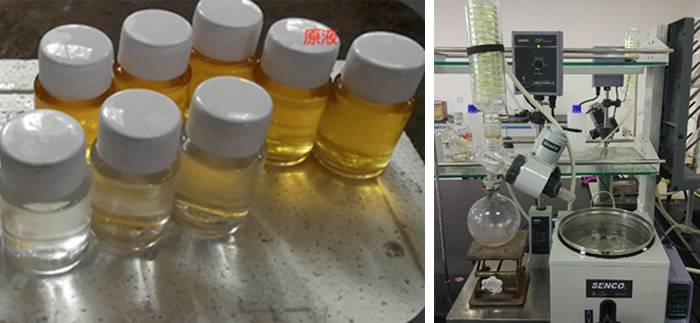

● determine the feasibility of separation

● determine achievable product quality and yield

● determine the process parameters of distillation

● monitor product characteristics during evaporation

● select evaporation system type, stage, rotor form, etc