Gas adsorption:

Granular and columnar beds, forward or reverse flow

Removal of hydrocarbons, ketones, esters and ethers such as ∨ OC benzene and toluene

Remove Nox

Removal of SO2, H2S organic sulfide, SO2, H2 S TCH

Removal of trace HCl gas

Remove cl2cl2 and HOCl

Removal of other organic substances

Waste gas treatment

Gas purification and on-line activation of activated carbon

Application of tail gas treatment in spray booth

Application of tail gas purification

Application of natural gas purification

Waste gas treatment package

Liquid adsorption:

Down flowing granular fill, pressure or gravity filter

Removal of residual argon, TOC / COD, organic matter and colloidal matter in water

Remove the color and impurities of industrial liquid

Remove degradation substances and avoid turbidity

Insecticide removal

Removal of halogenated hydrocarbon

Algal toxins

waste water treatment

Activated carbon industrial sewage treatment

Municipal water treatment application

Application of industrial sewage treatment

Application of decolorization

Application of beer and beverage industry

Complete set of wastewater treatment equipment

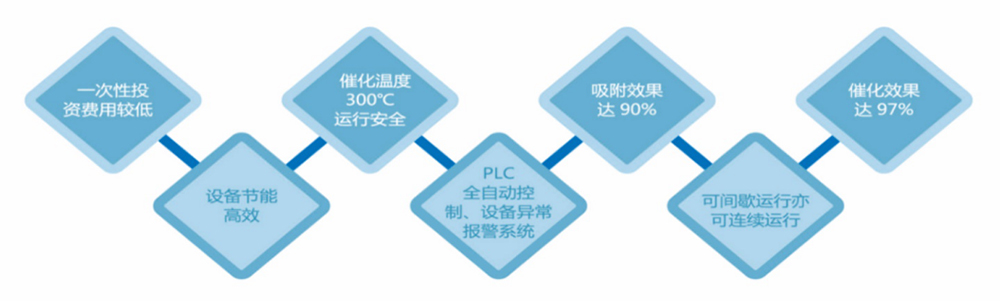

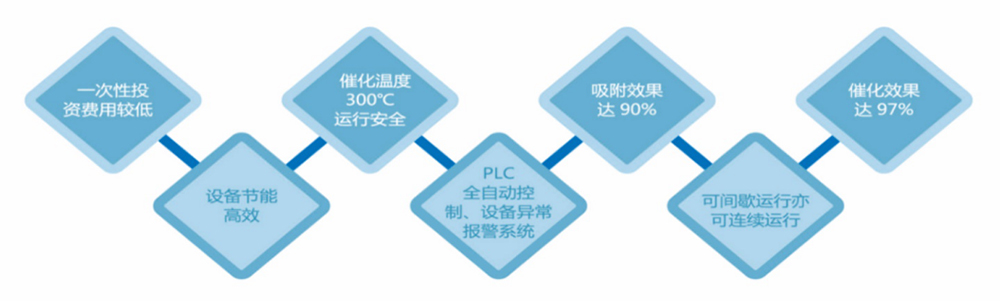

Technical characteristics

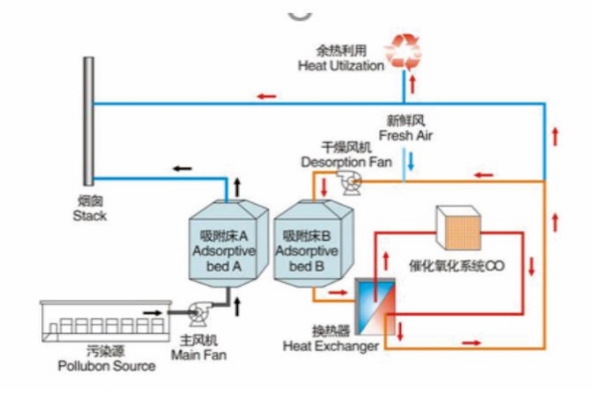

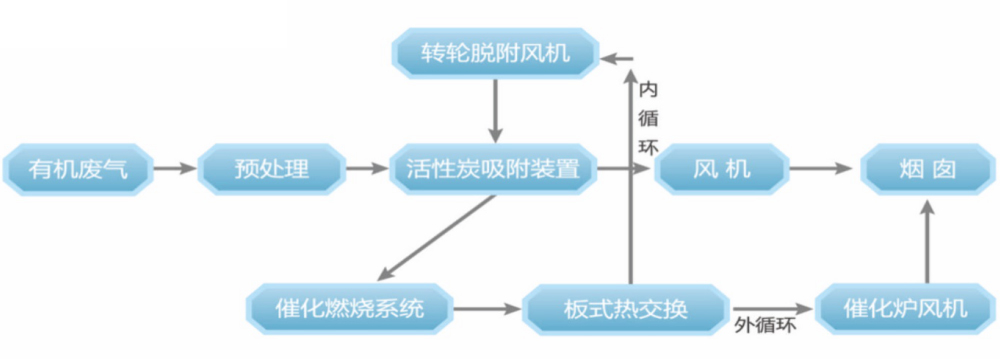

Activated carbon adsorption + catalytic combustion device

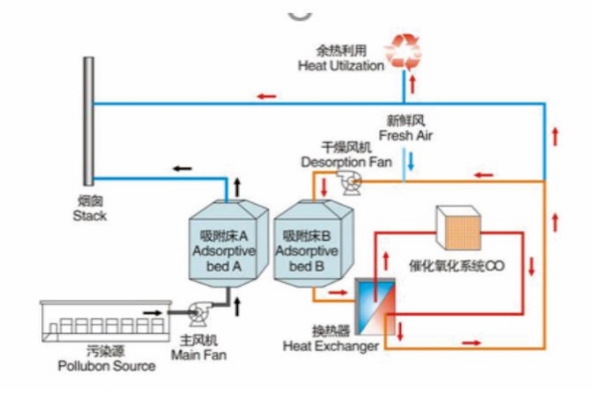

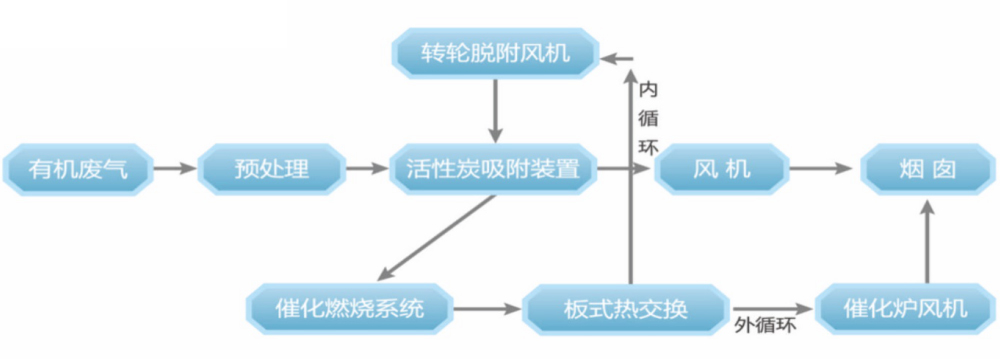

The organic gas adsorption catalytic purification device is suitable for the treatment of low and medium concentration organic waste gas. System principle: mainly according to the adsorption performance of porous activated carbon and the desorption performance of activated carbon at high temperature, the organics are respectively adsorbed and desorbed. The desorbed organics enter the catalytic combustion furnace at 300-400 ℃ for catalytic combustion to oxidize C and H compounds into CO2 and H2O, etc.

System process description

Applicable industries: spray paint, chemical industry, printing, coating, automobile spray paint manufacturing, ink printing and dyeing, paper making, injection molding, etc.

Torchi provides customers with cost reduction and cost saving solutions, and constantly optimizes and improves technical service capabilities.

Torchi can provide activated carbon adsorption test and regeneration services

Torchi adsorption test service:

There are many kinds of organic waste gas substances, and environmental testing institutions charge high fees! The company has developed a set of activated carbon waste gas adsorption test system based on the principle of "think what the user thinks, be urgent for the user". According to different waste gas mechanisms, suitable activated carbon can be filled to conduct adsorption test for the user.

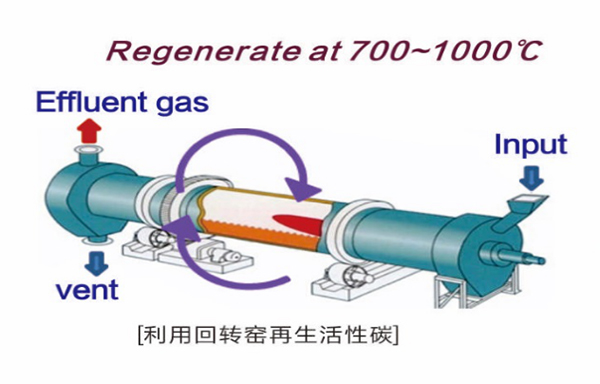

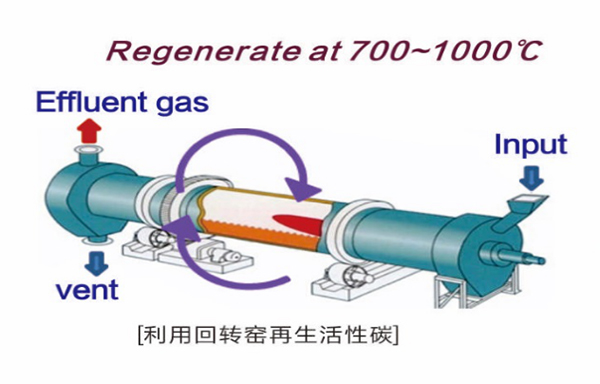

Traditional high temperature regeneration method

Regeneration can remove the adsorbed substance in the activated carbon which has lost the adsorption capacity and restore its adsorption function.

Torchi has established cooperation with foreign and domestic activated carbon plants to provide activated carbon regeneration services.

Torchi provides customers with cost reduction and cost saving solutions, and constantly optimizes and improves technical service capabilities

Torchi can provide activated carbon adsorption test and regeneration services

Torchi activated carbon regeneration service: low temperature regeneration method and principle

Regeneration can remove the adsorbed substance in the activated carbon which has lost the adsorption capacity and restore its adsorption function