Surface filtration

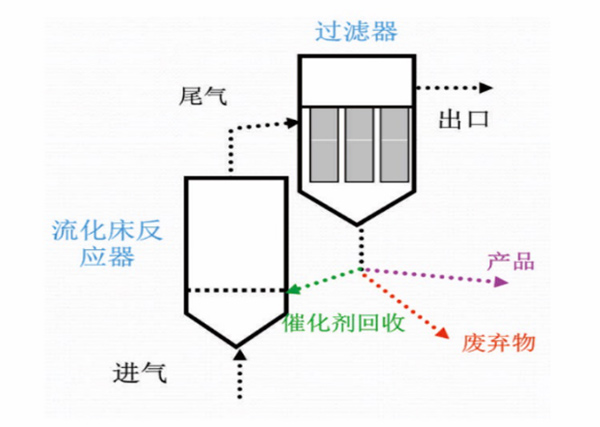

a) Remove solid particles from the air stream

b) Catalyst recovery in fluidized bed process

c) Tail gas purification and emission control

Deep filtration

d) Protection of downstream equipment (safety filter)

e) Protect compressor, heat exchanger and catalyst bed

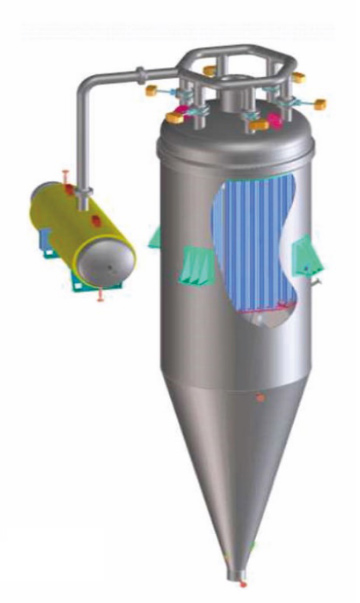

Catalyst filtration, decarbonization filtration, high temperature filtration, high viscosity filtration, high corrosion filtration, automatic back blowing filtration

Catalysts and cracking agents used in refining and chemical units, as well as solid-phase catalyst production involved in petrochemical industry, belong to the field of high-tech content. These catalysts contain a variety of harmful heavy metals and produce a lot of dust in the production process.

Recently, due to the more stringent requirements of environmental protection, the dust particles discharged from the catalyst production unit are strictly monitored.

The production process of catalyst involves the dissolution and dispersion of metal salt, the loading and precipitation of carrier oxide, drying, calcination, decomposition, reduction, aging and other processes. The high efficiency gas-solid separation technology is adopted in the production process of these catalysts, which can not only recover the catalyst particles with high value, but also reduce the production environment atmosphere and exhaust catalyst particles content, which is of great significance to the health of production workers and environmental protection.

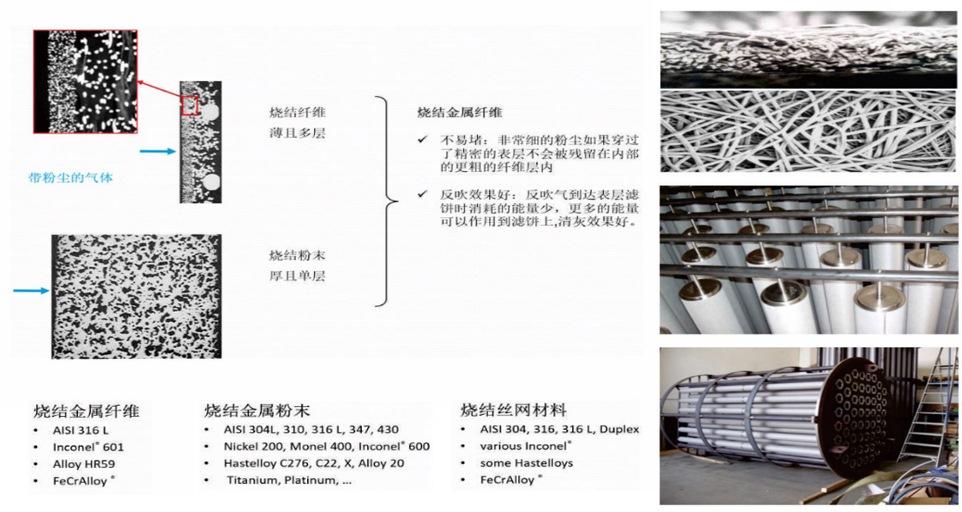

Filter element: made of metal sintered fiber, sintered powder and sintered wire mesh.

Features: high strength, high temperature resistance, corrosion resistance, easy back blowing.

● filtration efficiency up to 99995% @ 1 μ M

● low emissions (minimum may be less than 1mg / Nm3)

● low pressure drop (< 10mba) → longer blowback period

● higher flow rates or smaller footprint

● less blowback gas consumption

● reliability and service life: less impact on process, short downtime and less maintenance required

● corrosion resistance, high temperature, high pressure - some filter materials are suitable for 800 ° C process

● online back blowing and soot cleaning regeneration

● completely made by sintering and welding without contaminants such as adhesives, glues, etc

● High strength, good resistance to mechanical and thermal shock - non fragile, metal fiber will not fall