This series of filter separators are mainly used in situations where solid and liquid particles need to be removed efficiently, regardless of particle size, and are especially suitable for removing extremely small floating dust and smoke. Its application is very extensive, including the removal of lubricating oil from process gas, the removal of inclusions in the natural gas pipeline upstream of compressor station and regulator station, and the removal of ethanol from dehydrated gas.

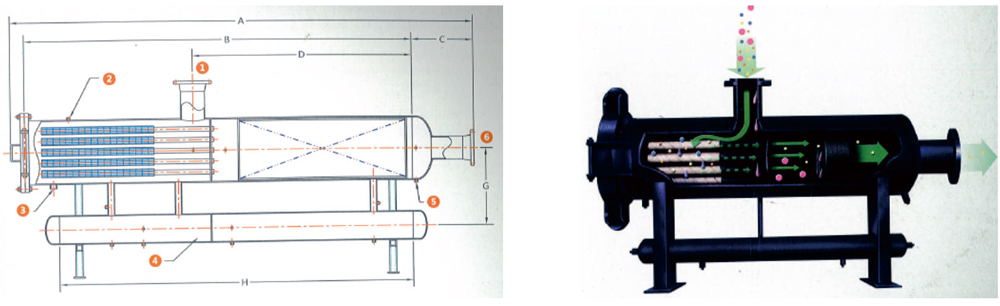

With the combination of TW wire mesh demister and TW coalescing filter element, this series of separation filters can 100% separate droplets larger than 3-5um, 90% separate droplets of 0.5-3um, and completely filter solid particles to 0.5um/99%.

In this series of separation filters, the combination of TW blade separation and TW coalescing filter element can separate 100% of the droplets larger than 5-8um, 90% of them can separate 0.5um-3um droplets, and the solid particles can be completely filtered to 0.5um/99%;

The vane separator can deal with various medium with different gas-liquid ratio, and can effectively solve the large amount of liquid carried in the gas.

◆ blade element can be fixed or movable

◆ adopt welding or bolt fixed bracket

◆ self cleaning system can be added

◆ multiple flow distribution structures can be added

◆ product recovery (methanol, ammonia)

◆ transmission pipeline, main transmission station and gas collection system

◆ compressor inlet separator

◆ fuel gas scrubber, combustion gas scrubber

◆ evaporator of pulp mill

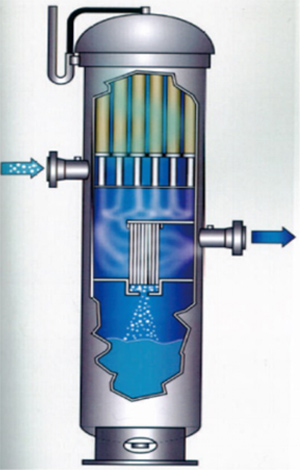

This series of cyclones is composed of multiple cyclones and filter elements, which are used to separate liquid drops and particles in gas.

According to the medium type, the equipment can be divided into gas-liquid separation, gas-solid separation and gas-liquid-solid three-phase separation.

Primary filtration:

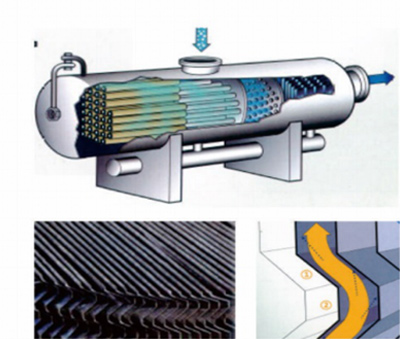

Cyclone tube type gas-liquid separator: when liquid containing gas enters the gas-liquid separator, strong vortex motion will be generated due to the design and distribution of the rotating vortex in the cyclone tube, thus forming a strong centrifugal force, making solid particles and liquid impurities stick on the wall of the cyclone tube. After the impurities are separated from the air flow, they gather in the liquid accumulation area of the container. The purified gas leaves the cyclone separator with the minimum pressure loss and enters the next stage of filtration.

Secondary filtration:

Filter element filtration and separation: this stage is composed of several replaceable or repeatedly cleaned filter elements. The type and accuracy level of such filter elements shall be selected according to the working parts, with the purpose of removing the smallest solid particles.

Oil gas water three-phase separator is one of the most commonly used equipment in the process of oilfield development and production. Commonly used oil, water and separation devices include: inlet buffer, oil gas water coalescer (corrugated plate packing), and gas outlet demister.

|

|

|

|