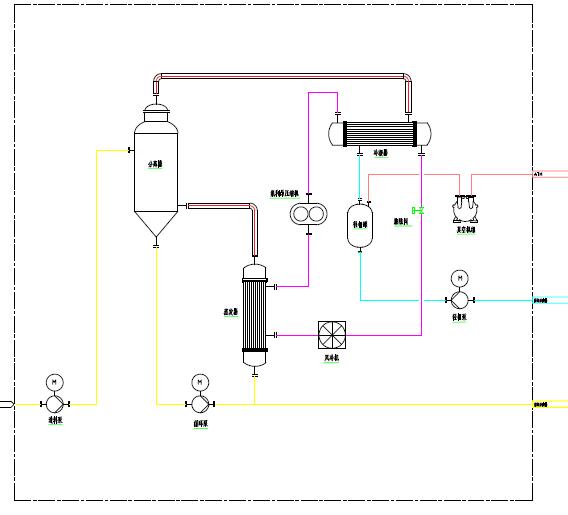

The equipment is fully automatic. When the original water barrel reaches the medium level, the evaporator will automatically feed water, the water pump will run to generate vacuum, and the compressor will run to generate heat to heat the waste water in the evaporation tank. In the vacuum state, the temperature of waste water will rise to 30 ℃, and the waste water will start to evaporate, and the preheating is completed.

1. The evaporation temperature is low, so it is not easy to produce scale, and the water quality is good.

2. There is no need for flocculation before evaporation, no need for Biochemistry after evaporation, and the wastewater treatment process is simple;

3. The system is fully automatic, remote monitoring, low energy consumption;

4. Module design, short delivery time;

5. The low-temperature heat pump technology is originated from the principle of industrial air conditioning, with mature technology, and accessories can be purchased and maintained at any time in the market, with very low maintenance costs.

1. Tc-dr type, working pressure is about 6kpa, evaporation temperature is about 40 ℃, suitable for scaling, precipitation, corrosion and other conditions.

2. Tc-gr type, with working pressure of about 5kpa and evaporation temperature of about 30 ℃, can clean the evaporation chamber and provide higher concentration of heavy phase liquid.

|

TC R 0.5 |

0.5-1 Tons / day |

200-250 Ton / year |

|

TC R 1 |

1-2 Tons / day |

250-500 Ton / year |

|

TC R 2 |

2-3 Tons / day |

500-900 Ton / year |

|

TC R 4 |

3-5 Tons / day |

900-1500 Ton / year |

|

TC R 6 |

5-7 Tons / day |

1500-2000 Ton / year |

|

TC R 8 |

7-10 Tons / day |

2000-3500 Ton / year |

|

TC R 12 |

10-15 Tons / day |

3500-4500 Ton / year |

|

TC R 24 |

20-30 Tons / day |

7000-8000 Ton / year |